hardness test of different materials|types of hardness testing methods : store Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).

15 de ago. de 2023 · No Portal do Cliente Affix, você pode consultar e pagar o seu boleto, além de outras informações e benefícios do seu plano de saúde. Saiba .

{plog:ftitle_list}

Novinhosdaimperium AKA Novinha Da ImperiumWoman, Amateur, 23y. Subscribe 110.6k. Add to friends. Videos 201. RED 273. Fans. Loading failed! Click here to retry. Novinhosdaimperium,Novinha Da Imperium,free videos, latest updates and direct chat.

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .The Brinell Hardness Test described above is called ?HB 10/3000 WC? and was the type of test used by the Germans in World War II. Other types of hardness tests use different materials for the sphere and/or different loads. Softer . Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel . Mohs Hardness is more like a comparative hardness test where the material is compared for indentation against a known material or hardness value. . Different Rockwell Hardness Testing scales are given in the below .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Indentation depth can be used to reflect the hardness of materials. To adapt to different soft and hard materials, many grades of hardness testers use different indenters and loads. One common grade is C, HRC .

Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).Material selection: The Brinell hardness test can be used to compare the hardness of different materials and to select the most appropriate material for a specific application. For example, it can be used to compare the hardness of different types of steel or to compare the hardness of steel and aluminum alloys.

Concora Medium Fluter fabrication

Hardness tests are used to measure a material’s resistance to: Wear; Drilling; Scratching; indentation; What are the four types of hardness testing? Several hardness tests can be performed based on this definition including; Brinell Hardness Test (ASTM E10) Rockwell (ASTM E18) Vickers; Knoop ; Brinell v Rockwell Hardness Test Hardness Test .

Hardness testing is a fundamental material science technique that measures a material’s ability to resist deformation. It is an essential parameter in the manufacturing industry, as the hardness of a material can affect its strength, durability, and performance. . There are several types of hardness tests, each designed to measure different . D ue to the simplicity of the experiment and the possibility of in-service inspection, the instrumented indentation technique is being increasingly used to study the mechanical properties (e.g., hardness and tensile properties) of films, coatings, and small-volume materials.[1,2,3,4,5,6,7,8,9,10,11] However, though different hardnesses (e.g., Brinell .differences between different materials, but not necessarily the differences between different materials of the same type. In carrying out this exercise, it should be noted that thickness of the material is a . In a hardness test an indenter is vertically displaced

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.Learn more about material hardness testing. How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . It is a measure of the materials hardness. There are several different tests used to display the hardness of materials including, Brinell (HB), Rockwell (HRC), Vickers (HV)and Leeb.Rockell is a depth difference method and measures a distance by applying different loads to a sample. Regardless of the indenter and test load, the testing cycle always follows the same pattern. . It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and .The hardness of the material is ranked on the scale between the material it just scratches and the material that it fails to scratch. Moh's Scale of hardness. Indentation testing. There are a number of different methods of testing the hardness of a material through indentation. The three most commonly used are the Brinell test, the Vicker’s .

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .between different materials of the same type. In carrying out this exercise, it should be noted that thickness of the material is a . In a hardness test an indenter is vertically displaced into the sample at a known speed until the resisting load reaches a certain magnitude. If the sample is not correctly supported then the displacement will be

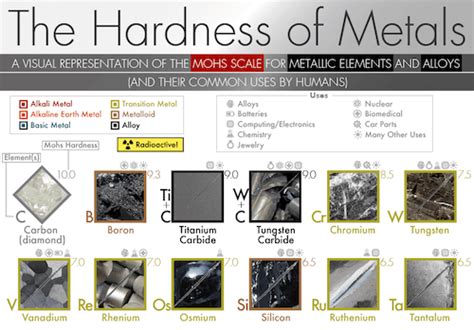

What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below.This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below). The Mohs hardness test uses ten reference materials with different hardness. The kind of material under test determines the kind of reference to use. The result is then obtained by assigning a numerical hardness value to the test material. Talk is the softest material used, with a value of 1. Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)

Case Depth Hardness Test; Measuring Material Hardness √ Rockwell Hardness Test. Rockwell Hardness test features over 30 different scales to choose from: hence you can select any suitable one for your material. The most commonly used scale for this type of test is “B” and “C.” This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test. . five specimens which were different in hardness and in material . A material hardness chart showcases the hardness ratings of different materials, evaluated using various hardness scales. This tool allows for easy comparison between materials or the selection of the most suitable hardness test for a specific material.

Sample cutter for CCT CMT fabrication

Essentially, hardness is only a measure of how well a material performs in a given hardness test. As a result, there are various hardness testing methods and techniques available to researchers today. In this article, we want to look into the four different methods of indentation hardness testing methods. Rockwell Hardness Testing

Knoop Hardness Test: The Knoop hardness testing measures the hardness of small and delicate materials, thin sections, and coatings. These test methods employ a rhombic-based diamond probe. The elongated shape allows for a precise diamond-shaped indentation on small, narrow surfaces. HK = (1.854 × F) / (I2) HK is the Knoop hardness value

automatic hardness testing. Note that softer materials are more sensitive to Figure 4: Vickers indents on the same rough surface preparation (9μm) for a) Hardened steel 715 HV 10 . Table 1: Surface requirements for the different hardness indentation tests. Dirt Simple fixture in Duramin-40. E Minor load e d 1 d 2 4

Circle sample cutter fabrication

types of material hardness

resultado promocional sorteo 4355 20 marzo 2021; resultado.

hardness test of different materials|types of hardness testing methods